1. Billet Casting Process

The billet casting process consists of 15 tonne melting furnace, holding furnace, refine furnace, filtering, same-level hot top casting, and 2 production lines, and is matched with bag-type dust removal flue gas treatment, homogenization treatment, could produce aluminum billet from 3 inches to 10 inches in diameter.

1. Extrusion Process

Our extrusion line, has gradient heating, variable frequency traction technology, so that we can squeeze thinner, smaller, more precise aluminum tubes and aluminum profiles.

Aluminum Pole Extrusion:

Lead to pull:

Straightening:

Cutting to length:

Heat treatment:

2. Machining process

Chalco Aluminum have several punching press, chamfering mahine and other machanical processing equipment, can meet the aluminum products after punching, tapping, bending, chamfering, cutting and other processing needs, can provide one-stop personalized service for customers in need of aluminum products.

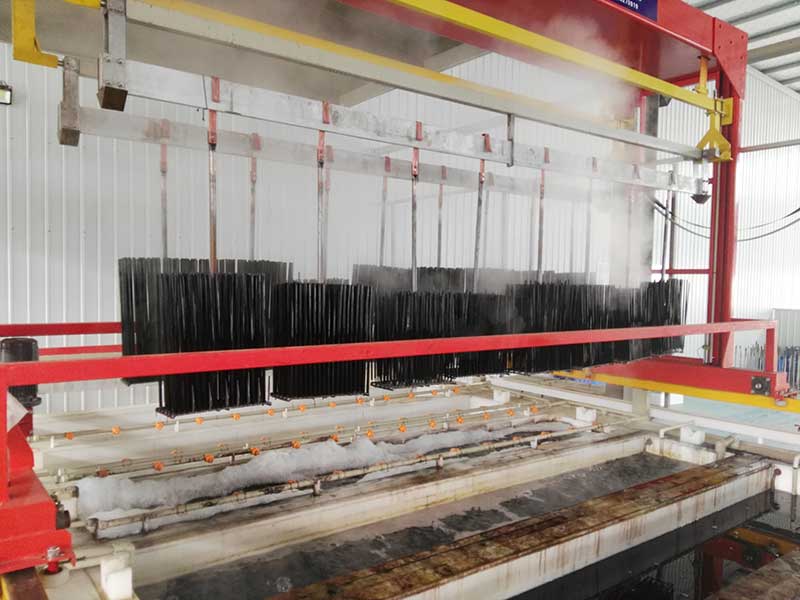

3. Anodizing process

Chalco Aluminum’s anodizing process has a full-automatic anodizing treatment production line, supporting polishing, brushing, sandblasting and other equipment. Chalco Aluminum are excellent in anti-corrosion, decoration, color anodizing. We could produce anodized work piece, which make our product are more widely used.